The Evolution of 3D Printing in Medicine: Custom Implants and Prosthetics

3D printing in medicine has revolutionized the way healthcare professionals approach patient care and treatment. The technology’s inception in the medical field brought forth a wave of possibilities, enabling the creation of customized implants and prosthetics tailored to each patient’s unique anatomy and needs. This groundbreaking approach marked a significant shift towards more personalized and precise healthcare interventions, opening doors to improved patient outcomes and enhanced quality of life.

As the capabilities of 3D printing advanced, medical professionals began exploring its potential in a variety of applications, from surgical planning and training to tissue engineering and drug development. The ability to fabricate intricate and patient-specific models provided surgeons with invaluable preoperative insights, allowing for meticulous planning and execution of procedures. Moreover, the advent of bioprinting technologies spurred research in regenerative medicine, offering hope for the fabrication of functional tissues and organs for transplantation.

The Impact of Custom Implants on Patient Outcomes

In the field of medicine, the utilization of custom implants has revolutionized patient outcomes. These personalized implants are tailored to match the individual anatomical needs of patients, leading to enhanced functionality and comfort post-surgery. Moreover, custom implants have shown to reduce the risk of complications and improve overall patient satisfaction rates.

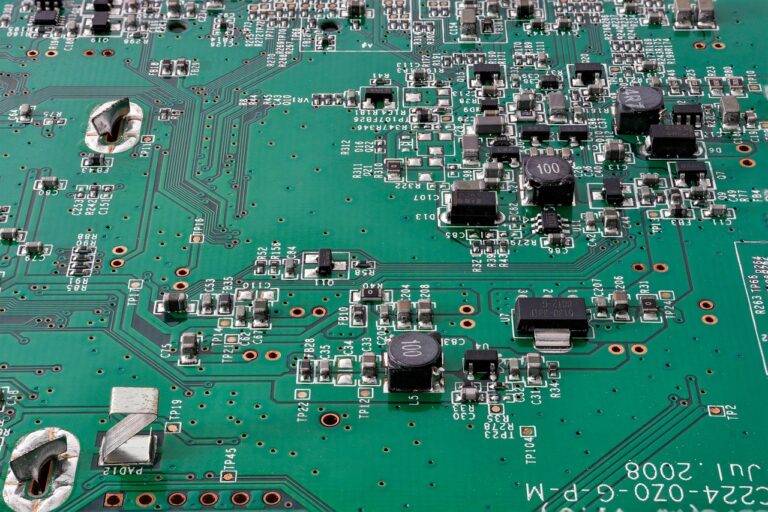

By incorporating advanced imaging techniques and 3D printing technology, healthcare professionals are able to create custom implants that perfectly fit the unique requirements of each patient. This level of precision not only ensures a better fit but also promotes faster recovery times and improved long-term outcomes. With the continuous development of customized implant solutions, the future of patient care in medicine appears to be increasingly promising.

Advancements in 3D Printing Technology for Prosthetics

3D printing technology has revolutionized the field of prosthetics by offering customized solutions for patients. Traditional prosthetics can often be uncomfortable and may not fit perfectly, leading to a lack of functionality and discomfort for the patient. However, with the advancements in 3D printing technology, prosthetics can now be tailor-made to fit the individual’s unique anatomy, improving both comfort and function.

Moreover, 3D printing allows for faster production of prosthetics compared to conventional methods. This rapid manufacturing process enables patients to receive their prosthetic devices in a shorter amount of time, reducing the waiting period and allowing them to regain mobility and function sooner. Additionally, as the technology continues to evolve, the materials used in 3D printing are becoming more durable and lightweight, providing prosthetic wearers with enhanced comfort and performance.

• 3D printing technology offers customized solutions for patients

• Traditional prosthetics can be uncomfortable and may not fit perfectly

• Advancements in 3D printing technology allow prosthetics to be tailor-made for individual anatomy

• Faster production of prosthetics compared to conventional methods with 3D printing

• Rapid manufacturing process reduces waiting period for patients

• Materials used in 3D printing are becoming more durable and lightweight, enhancing comfort and performance

How has 3D printing technology impacted the field of medicine?

3D printing technology has revolutionized the medical field by allowing for the creation of custom implants and prosthetics that are tailored to each individual patient.

What are the benefits of using 3D printing technology for prosthetics?

Using 3D printing technology for prosthetics allows for faster production times, greater customization, and improved patient outcomes.

What are some advancements in 3D printing technology for prosthetics?

Some advancements in 3D printing technology for prosthetics include the use of biocompatible materials, improved design capabilities, and the ability to create more complex and functional prosthetic devices.

How do custom implants impact patient outcomes?

Custom implants can greatly improve patient outcomes by providing a better fit, reducing the risk of complications, and enhancing overall comfort and functionality for the patient.

Are there any limitations to using 3D printing technology for prosthetics?

While 3D printing technology has many benefits, there are still some limitations, such as cost, material limitations, and the need for further research and development in the field.